Would you like to start a conversation with other industry leaders to brainstorm a challenge or to just know more on a particular topic?

Engage in online discussions with your Peers

Start NowMany organizations, especially those having a monopolistic or dominant market share, tend to develop a culture of “Continuous Crisis Management” – a rather negative culture which results in constantly dealing with problems. Such companies move from crisis to crisis. Once a crisis surfaces, a trouble-shooter usually emerges who douses the fire, earning the appreciation of the top management. Almost no effort is made to evaluate why the crisis occurred in the first place. Eventually, this becomes the norm rather than the exception and regular trouble-shooters are given preference over all other people.

Symptoms of an Organization where Crisis Management has become a Habit

The primary symptoms of such a culture are:

- Ignoring the warning signs – Warning signs of problems affecting business are either ignored or not known due to absence of any structure to recognize them. Action is taken only when problems turn into crises, requiring massive efforts.

- Performance drop – Many problems are dealt with inadequately, virtually no improvement effort is made and many opportunities are lost. The overall performance of the organization drops drastically.

- Weak structured management approach – Due to so many crisis situations, only people specializing in troubleshooting and managing crisis are recognised. Those who advocate a structured process management approach are pushed back each time.

- Shortage of time – Those responsible for the betterment of the organisation are so busy in their tasks that they have absolutely no time to look into the problems of the business as a whole.

- Implementing half-baked solutions – Many problems are solved by just treating the symptoms rather than looking at the root cause of the problem and fixing it. As a result, many old problems simply reoccur or contribute to other problems, making them more serious.

- Urgency preferred – Occurrence of crisis in different parts of business is a common thing in such companies where rules are made just for formality. Long term improvement efforts and bringing in a process management culture are frequently negatively impacted to deal with these immediate crisis situations.

Continuous Crisis Management becomes a science of vague assumptions which is based on assume figures, and developed from inconclusive observations. Such figures or observations could well be arrived through dubious methods or measured with equipment of questionable accuracy. Often, these are presided over or managed by people with low understanding of the larger business interests, short term vision and an attitude of keeping it on the backburner – and it stays there till it becomes a raging fire.

In the real world, such an approach can possibly be successful where organizations enjoy monopolistic positions or hold dominant market share but can prove to be disastrous whenever they face some serious competition or if the market conditions change.

…the improvement process becomes the norm rather than just a one-time effort. The solution is to replace the prevailing culture of “Continuous Crisis Management” with that of “Continuous Improvement” by implementing Lean principles.

Developing a Culture of Problem-solving

In the business world, it is gainful to standardize processes for developing cost efficiency and improving process outputs. After some time however, whatever gains that were secured might erode when the improvements become part of the standard process. Along the way, some stagnation might also creep in. To avoid this, a dynamic approach should be taken to see that the improvement process becomes the norm rather than just a one-time effort.

The solution is to replace the prevailing culture of “Continuous Crisis Management” with that of “Continuous Improvement” by implementing Lean principles. For this, we need to determine the:

- Customer Requirements - Generating value for the customer should be at the core of everything. Anything that does not meet this test should be systematically eliminated.

- Business Requirements - To develop the focus and capabilities to sustainably fulfil the customer needs

- Process Requirements - To make the process efficient by identifying the bottlenecks and waste elements in the process and systematically work to eliminate them

Once these requirements are determined the processes can be optimized, organizational structure defined, and IT/ operational strategy put in place to synchronise with the business strategy. As a result, all the problems and issues can be solved through a structured process by a multi-skilled team, which consists of people with the required skills and training to develop and implement solutions.

The principles of such a team would be to:

- Do a careful analysis of the problem. Either solve the problem if its root cause has been identified or look for any quick fix solutions till the root cause is identified.

- Discourage quick-fix solutions without identifying the root cause. Quick-fix solutions may be implemented only after careful evaluation.

- Avoid solving individual problems unless it assumes critical proportions.

- Train the problem-solvers to go for the root cause and not just the visible symptoms.

- Encourage and develop a mindset of preventing problems rather than solving them after they have occurred.

- Encourage rewarding persons who practice prevention and systematic problem solving. Even the “trouble shooters” should be rewarded for problem solving through RCA.

- Apply solutions only after evaluating their impact.

- Prioritize problems and address the most serious problems first.

- Set realistic timelines to avoid last minute issues.

- Develop a structured and systematic approach to problem solving using the RCA or 8D or any other robust problem-solving methodology.

Having such an approach would free up the leaders and others in the organization from constant problem solving and focus their energies on more productive efforts, which would help the organization to grow and improve faster than its competitors.

Case Examples of Problem-solving Culture

Some of the examples which might benefit the organization are described below.

Time taken to generate sales related quotations can be reduced by capturing all the expense line items and product-wise profit margin percentage (as decided by the organization). In case all expenses and margin percentages etc. are readily available, it will be very easy for the Sales department to generate quotations and get quick sales orders from customers. It will also improve positively the overall Order-to-Cash process.

Creating financial reports is a regular task. The customers of these financial reports are either internal stakeholder (like decision makers within business) or external stakeholders (like investors, lenders, regulatory bodies, etc.). Investing in technology to get ready-to-use reports, as per the customers’ requirements or getting ready-made data with minimum manual effort can be highly useful to save time and effort. It provides the output which is relatively error free and consists of only useful data, devoid of any data points which are of no use to the customers.

F&A is generally deadline driven where meeting the due date is very critical for all the processes, be it AP or AR or compliance related. Technology should be leveraged to get reminders ahead of time to help in crucial process, such as:

- Arranging funds in advance for making payments to earn discounts from vendors and also earning goodwill for the organization,

- Sending reminders to customers before due date of receiving payments in order to keep the overdue amounts within manageable limits, and

- Punctuality in compliance related matters, which will help the organization to avoid any legal or regulatory hassles.

Accounts Receivable data can provide the history of late payments by big customers. By analysing this data, the Sales department might be able to offer attractive discounts for large orders in case the payments are made on time or before the due date.

An analysis of employee expense reports often reveal that a huge part of travel expense is due to employee travel from one company location to another for meetings. A possible solution could be to encourage the employees to do virtual meetings to reduce travel expenses.

Employee Claims & Reimbursements constitute a large part of the work of any Finance department where countless employee claims and their supporting documents are processed, validated and paid to employees. It may be a good idea to give out company issued credit cards (card limit linked to designation or some other criteria) to pay their official expenses. The Finance department can simply check the softcopies of credit card statements and make payments for the valid expenses and recover the rejected expenses from the employees’ remuneration.

Suppliers’ data analysis often reveals continuous quality problems with the material supplied by some important supplier. Procurement teams may work with the existing supplier to understand and solve the issue or look for alternative suppliers.

Analysis of sales data may help in identifying a market segment which is too small to warrant visits from the sales team. Alternatively, some new market segment could be identified which holds great promise and require more focus by the sales team for future growth.

Concepts like LIFO and FIFO can be used innovatively to optimize costs by ensuring better utilization of budgets of operational projects. Effective monitoring of project completion results in proper resource utilization. The projects will prove to be cost-effective, as planned and timely project completion will ensure that ensuing gains will start flowing within the planned timelines.

Better Processes and Problem-Solving

Experience demonstrates that changing the way work is organized has a more profound and lasting impact on culture than just educating employees in problem-solving methods. Traditional organisations are normally run in a tightly knit hierarchical structure like military units or bureaucracies where power and decision making are enjoyed by few people at the top. All the decisions reach the frontline workers after passing through several layers of middle management and very often, the message either gets diluted or distorted, thereby leading to negative consequences and waste. Similarly, the concerns and suggestions of the lower levels reach the top after passing through several levels, keeping the lower-level people waiting forever for the outcome. This often results in employee and customer dissatisfaction, thereby leading to situations where both employees and customers start looking for alternatives.

Lean helps an organization in improving customer value, elimination of waste and optimum use of resources. It helps an organization save cost and time by eliminating all kinds of waste which improves efficiency and profitability. As a result, the end-customer is delivered with a better-quality product or service at the proper time and at an affordable price, which results in customer satisfaction and improved sales for the organization and its partners.

Lean also helps in building a culture that respects all employees at all levels and empowers them to share their ideas to being improvements in their work areas and processes.

- Improving the quality of its work processes

- Reducing errors or defects in work processes

- Reducing Costs

- Improving flow of the process

- Simplifying complex processes

- Reducing Lead Time

- Improving employee morale

- Efficient utilization of resources

Lean is the beginning of the journey of continuous improvement. Lean techniques are not simply management tools but rather they embody a culture that needs to be enforced from the top leadership down throughout the company. Systematic implementation of Lean techniques in all areas of working can actually yield benefits that other improvement methods cannot.

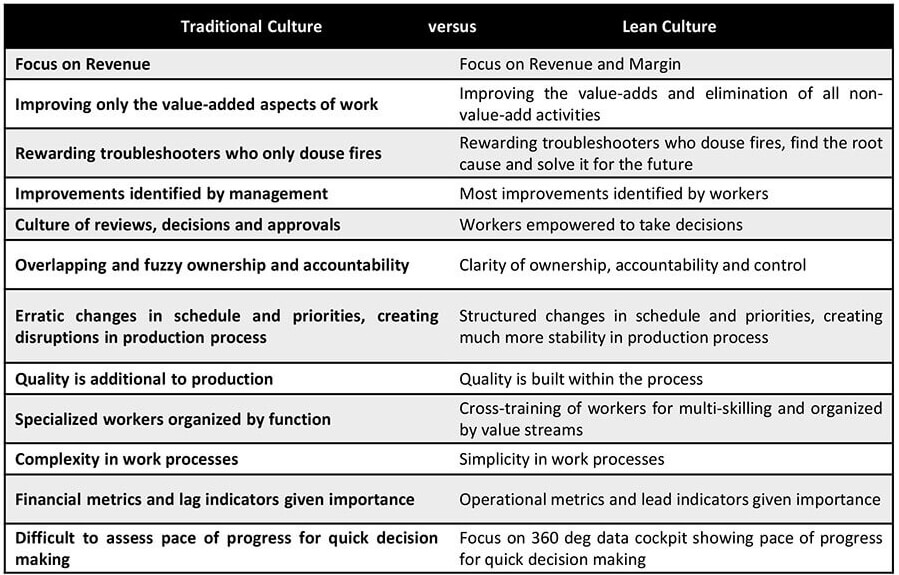

Key Differences Between Traditional and Lean Cultures

When a company engages its people in problem solving as part of their daily work, they feel more motivated, they do their jobs better, the organization’s performance improves, and a virtuous cycle starts to turn.

Employee Engagement

Organizational culture is not a ‘Plug and Play’ tool which can change overnight. It is a very dynamic instrument which needs painstaking efforts to install and requires absolute trust between the top and lower levels of management. A Lean culture is implemented in business processes with an aim to generate more value for the customer, thereby making the customer and the business ‘winners’ in the game. Clearly, this is not possible if employees are left out. The employees need to become winners first and be engaged in continuous improvement and creating more value for the customers.

This can be directly linked to one of the basic principles of Lean – “Respect for People”. It means helping every employee to realize their full potential and empowering them to take ownership in their work and take pride in their achievements. This also includes providing the workers with the resources to solve their problems and empowering them to improve their work processes, wherever required. When a company engages its people in problem solving as part of their daily work, they feel more motivated, they do their jobs better, the organization’s performance improves, and a virtuous cycle starts to turn. Such an approach can tap enormous potential for the company and its customers.

Conclusion

Business organizations today are deeply inter-connected globally and are severely impacted by the global pandemic and disruptions in multiple regions and countries. An organization has to continuously keep on adapting to face these challenges and to remain relevant in the marketplace. Having a continuous crisis management approach to business may have been useful in the past or in monopolistic business environment, but this is becoming very rare. Things like delayed decision making, losing opportunities, waste in work processes, incorrect people selection, etc. can cost a business organization heavily.

What is needed for business organizations to survive and thrive in business arena is to incorporate Lean principles in their business strategies and policies to change its overall culture. A thriving employee engagement will make the workers take ownership of their work and take pride in their achievements, thereby benefitting the entire organization. Once the focus is on value creation and free flow of value in the organization, without any hindrances and obstructions, the number of benefits and positive outcomes that the organization will experience could be limitless.

Organisations primarily fixated on quick-fix solutions or troubleshooting only just to solve the visible problems will do well to focus on problem solving though a scientific approach by first identifying the problem, implementing any temporary solutions if required, finding the root cause of the problem with a multi-skilled team and then systematically implementing the solution to eliminate the problem for the future. The preparation and implementation of business strategy and the results of free flow of value creation will transform the whole organization and catapult it into higher leagues.

ABOUT THE AUTHOR

Jasmeet Singh Kohli

Senior Consultant & Project Analyst at Quintes Global, RavluE Group.

Jasmeet comes with over 16 years of experience, with long experience in Quality Assurance. He has carried out projects in multiple domains such as IT services, financial services, general insurance, location-based services, etc.

He has a knack of identifying pain areas and issues which obstruct the free flow of value in business processes. He has the unique experience of being an employee, a business owner and an external consultant and can see the issues from different perspectives which negatively affects a process from achieving its full potential and potential improvement opportunities.